fr-Uno System

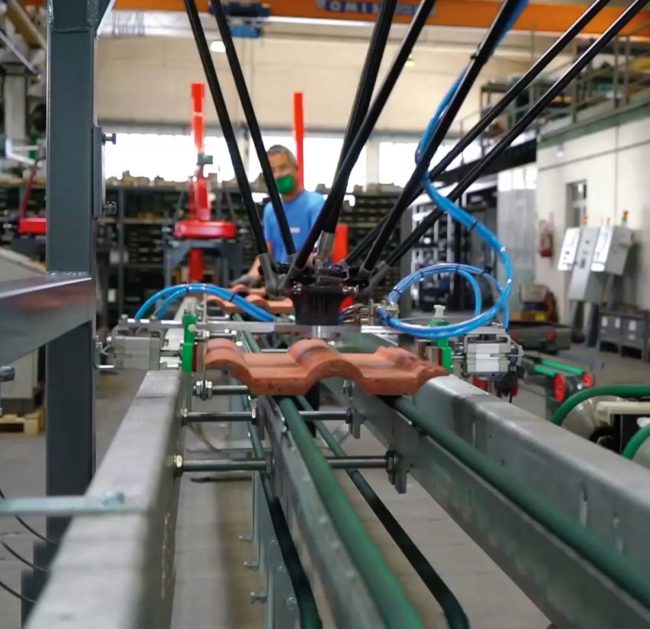

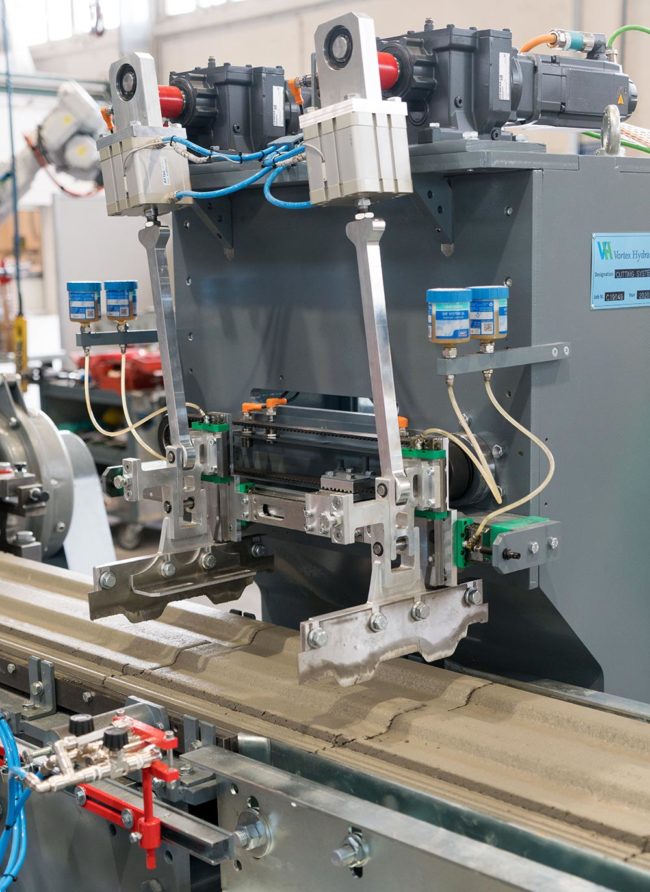

Uno machinery range is the right solution to start the concrete roof tile manufacturing business with low initial investment and the possibility to easily increase the production capacity up to 4 times more without need of buying a 100% new line. Uno systems production range varies from 800 to 12,000 tiles per shift (*).