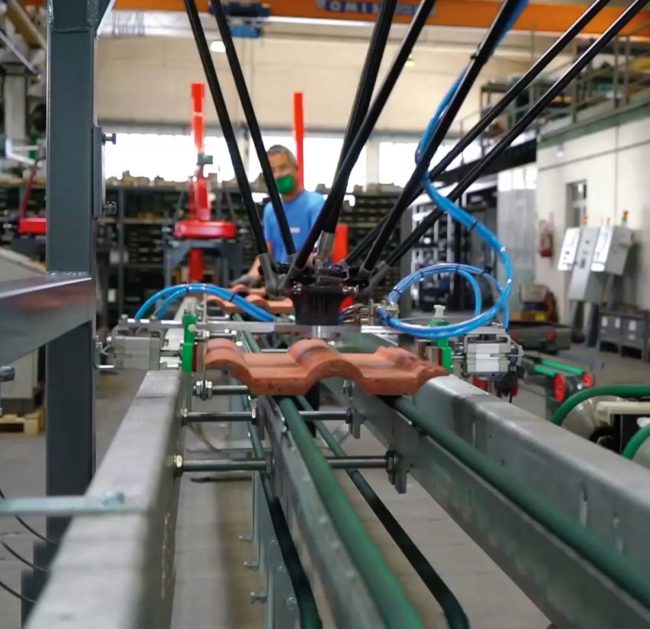

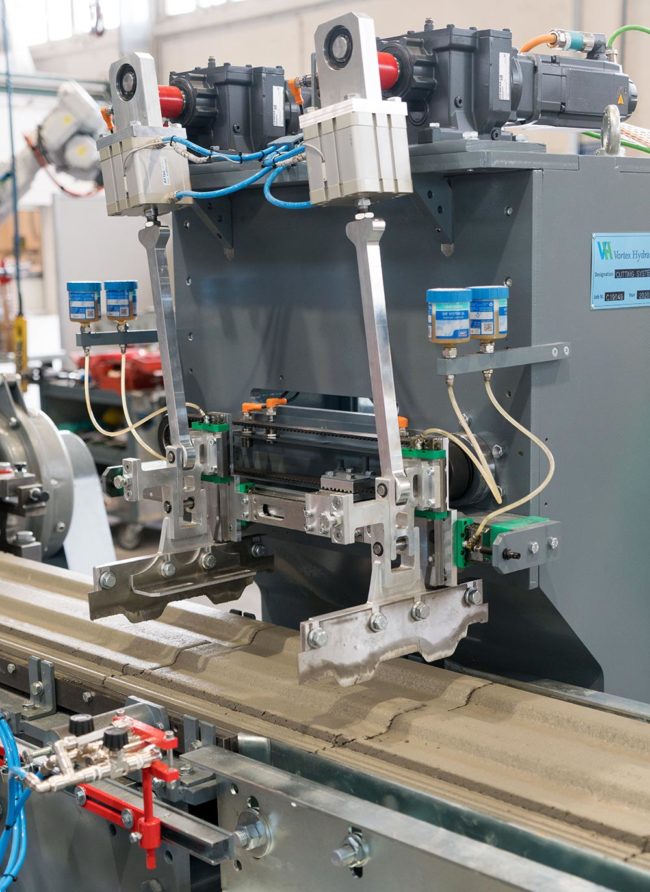

Remote commissioning of highly efficient customised robotized packing system

Innovation, customisation, efficiency, and specialist technical support are undoubtedly key words in the service Vortex Hydra offers its worldwide customer base. This has again been demonstrated by yet another successful installation & commissioning of a Vortex Hydra ‘state of the art’ automatic robotized roof tile packaging machinery. Having changed their machinery supplier to Vortex Hydra five years ago,…