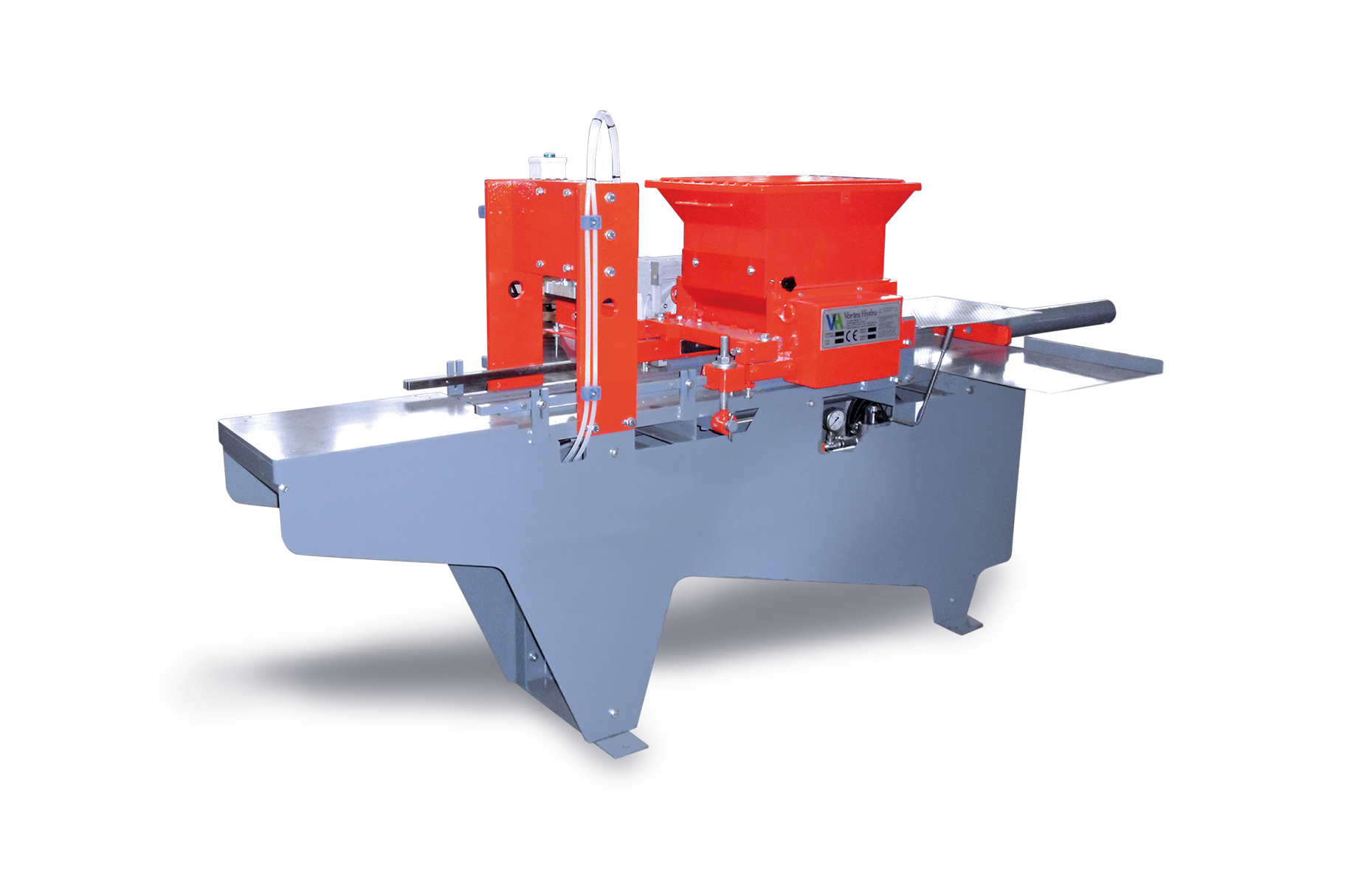

UNO SYSTEM

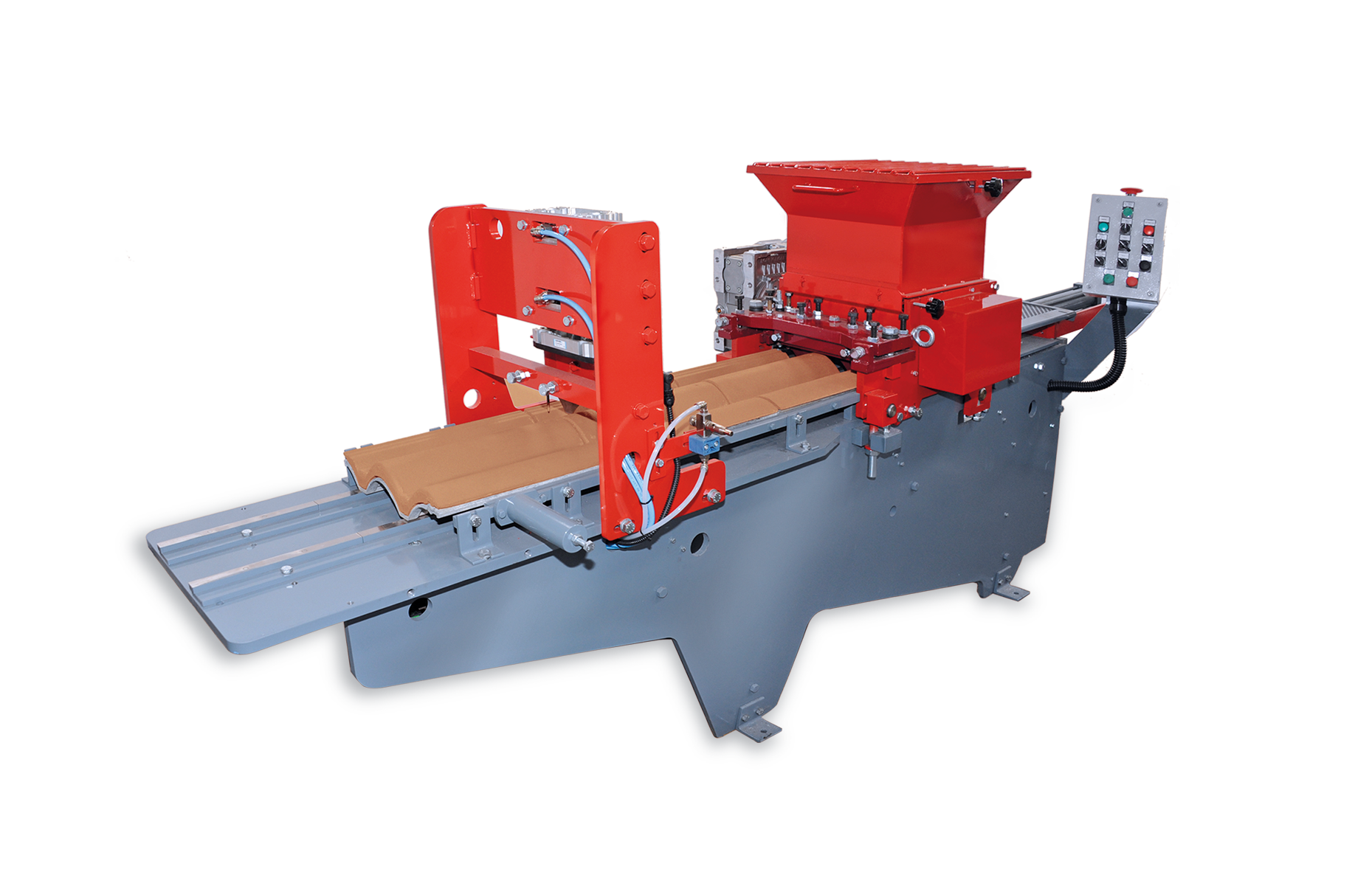

UNO+UNO TWIN STARTER PACK

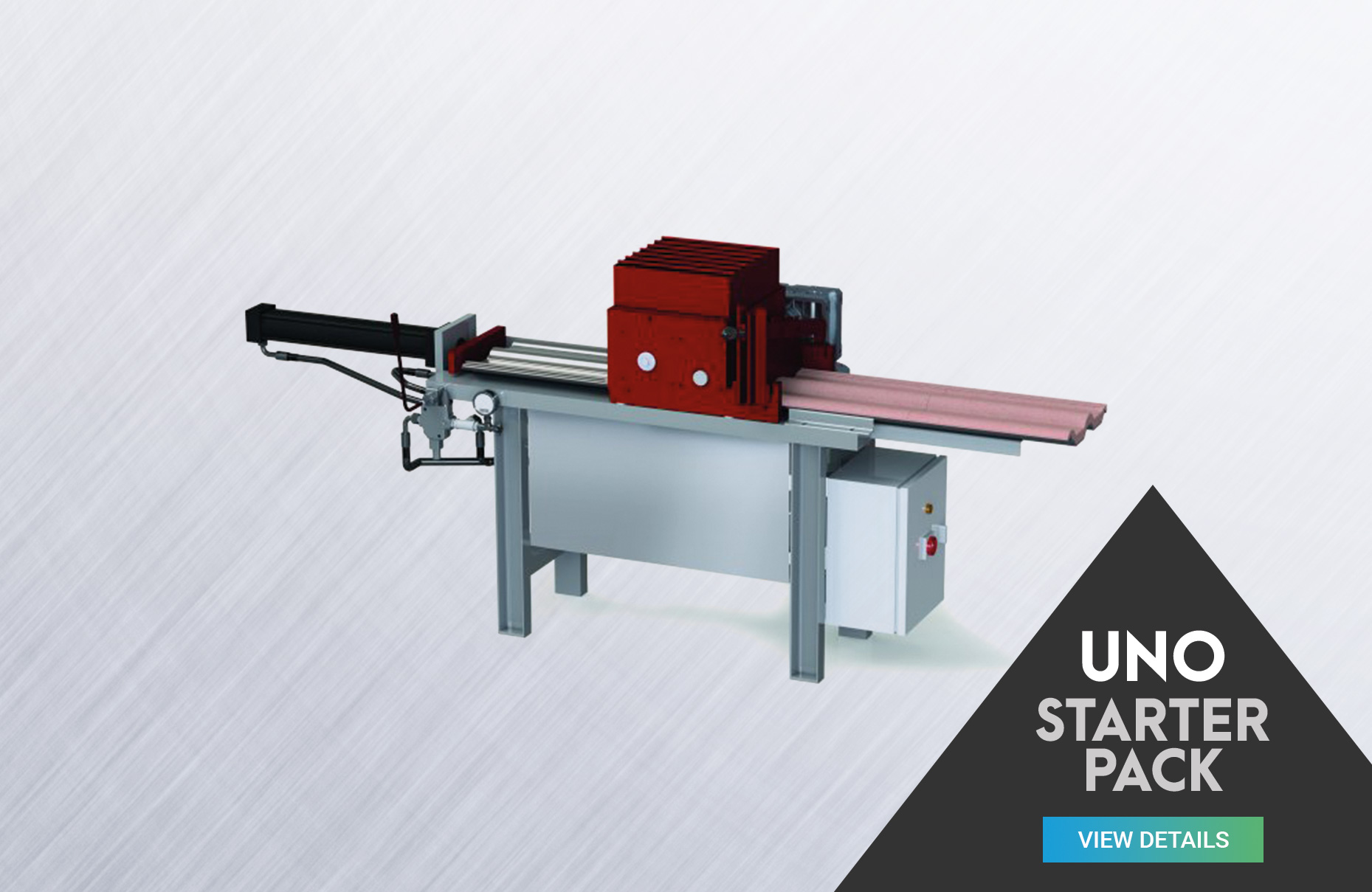

“UNO” STARTER PACK & “UNO+UNO” TWIN STARTER PACK

Both the “UNO STARTER PACK” and “UNO+UNO Twin starter pack” enables a customer to enter the building products market using small investment. Both these Starter Pack plants are very compact units and can easily be moved from site to site to suit a customer needs.

- The “UNO” starter pack is an ENTRY LEVEL small turn-key plant for the manufacture of approximately 83 sq.m. of “Double Roman” coloured concrete tile roofing per 8 hour shift.

- The “UNO+UNO” twin starter pack is s an ENTRY LEVEL small turn-key plant for the manufacture of approximately 58 sq.m. of “Double Roman” roofing and 28 sq.m. of “Multiple Square” floor coloured concrete tiles per 8 hour shift.

MAXIMUM OUTPUT

2 tiles/minute

INSTALLED POWER

~ 8 kW (mixer included)

PRODUCTION

up 1.250 tiles per shift

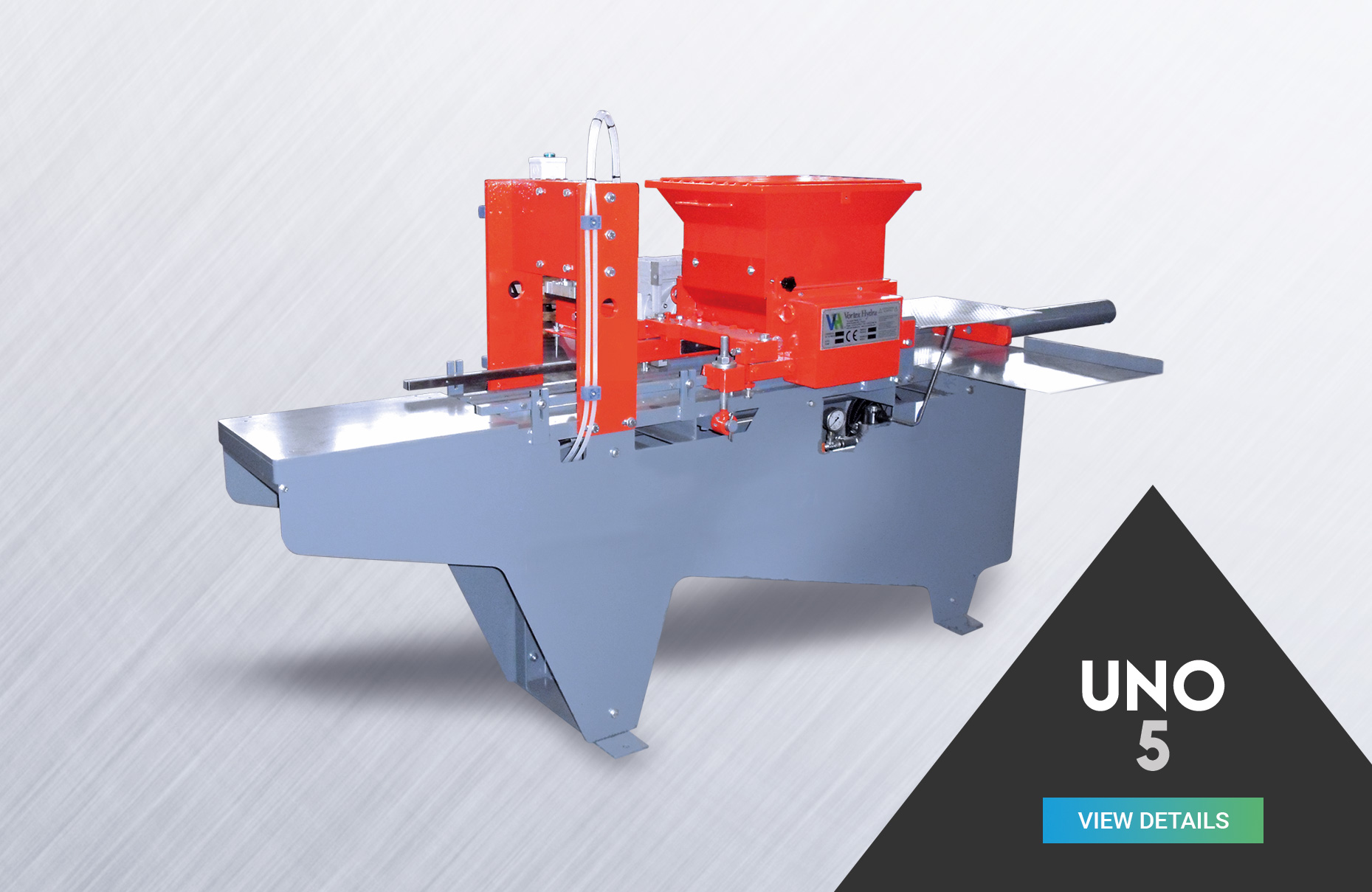

UNO 5

• This is a Vortex Entry Level plant consisting of a robustly constructed machine that ensures the production of high quality concrete roof tiles. The aluminum pallets, previously separated from the dry tiles, are oiled and manually placed into the tile machine whereupon they are pushed from their rear end back through the extrusion box.

• All mechanisms are manually controlled including the hydraulic pallet pushing cylinder. A simple mixer, provides the concrete that has to be produced to a high quality.

• It is a “multi-profile” machine – different tile types can be produced by it, simply by changing the extrusion head and the aluminum pallets to suit the different tile profile. Different facial tile types can also be produced on the machine.

MAXIMUM OUTPUT

5 tiles/minute

MINIMUM BUILDING SIZE

14 m x 12 m x 5 m high

INSTALLED POWER

~ 12 kW (mixer included)

PRODUCTION

2000 tiles per shift

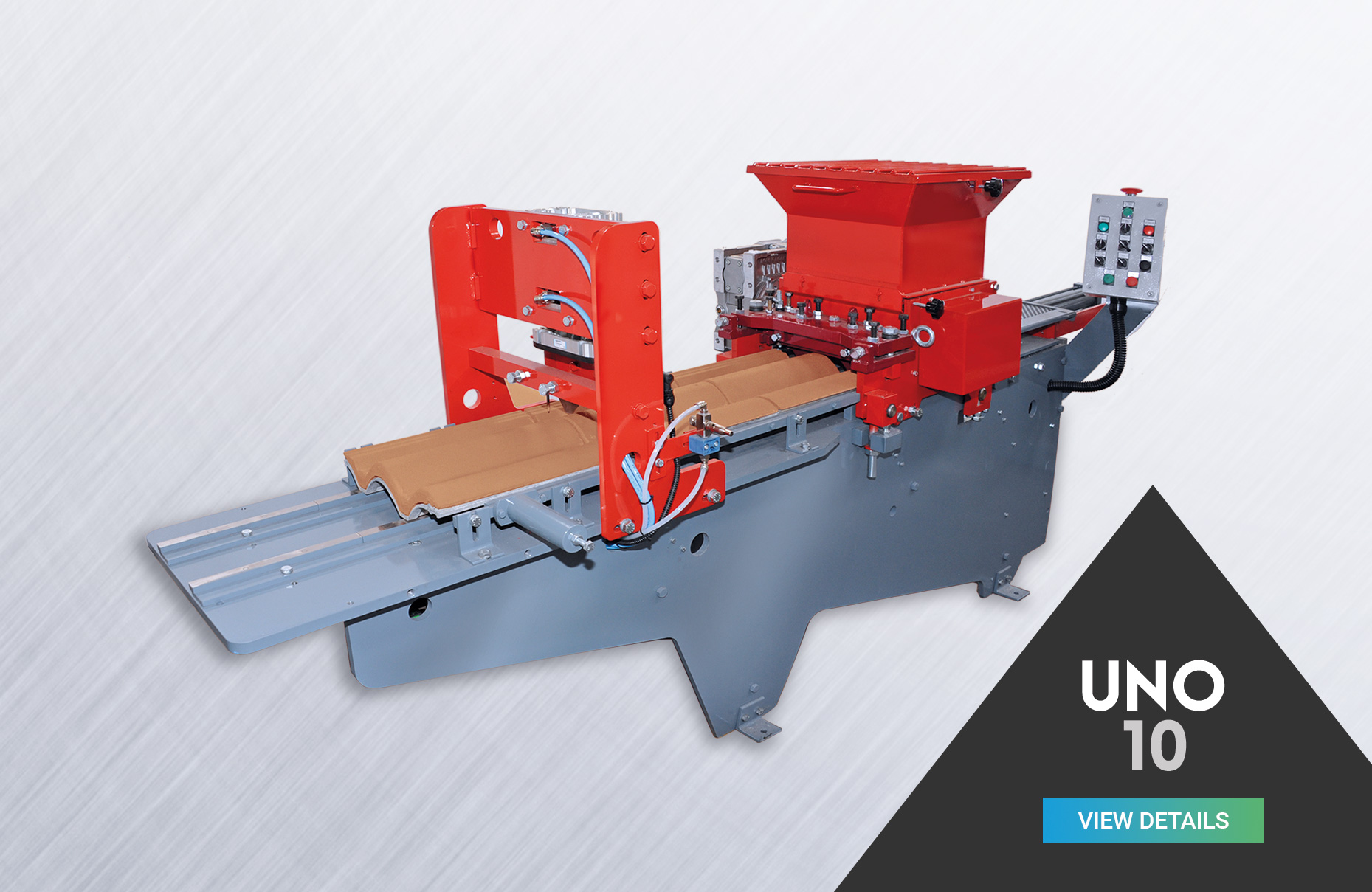

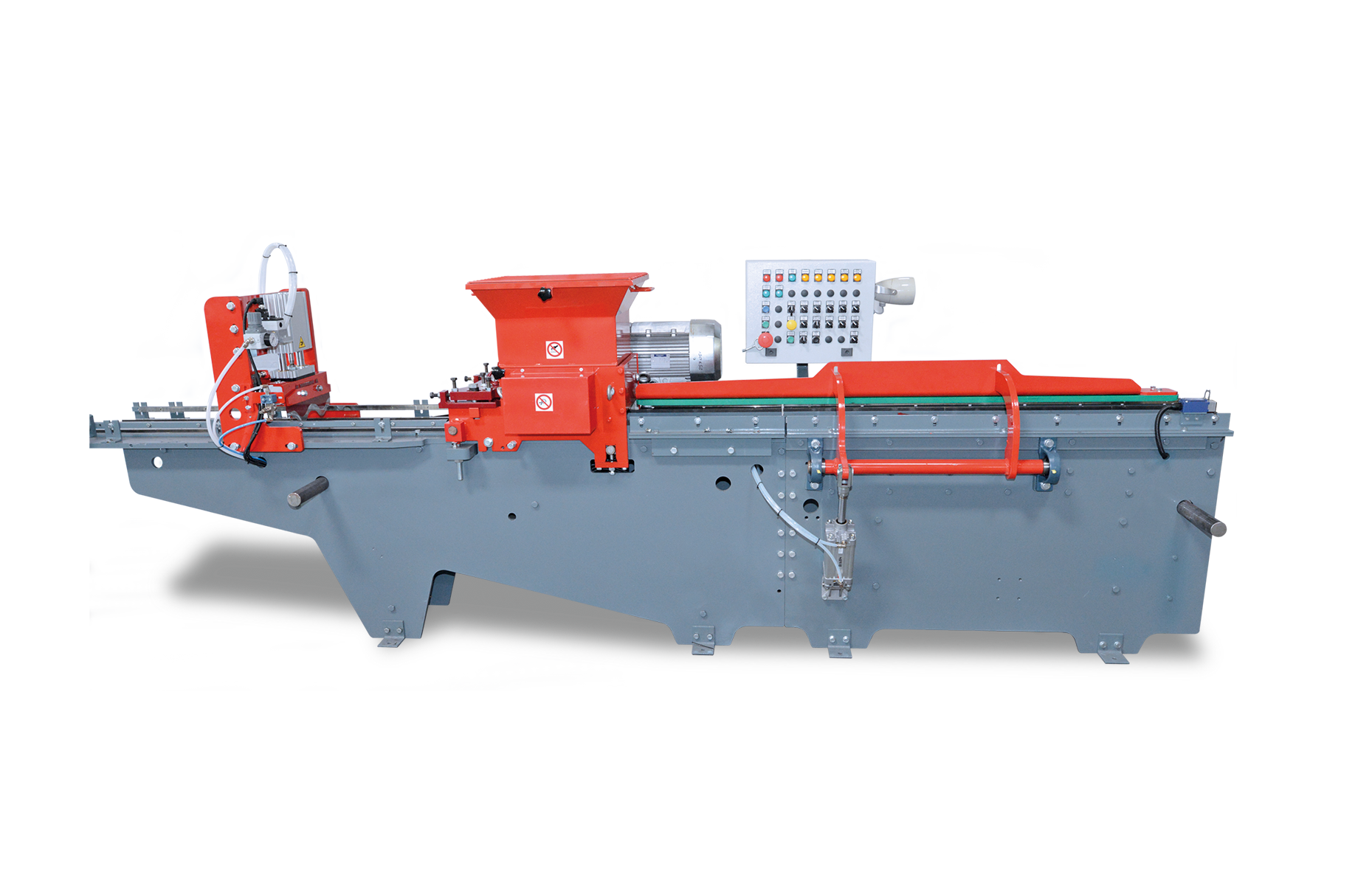

UNO 10

• The UNO 10 is an ideal solution for an organisation or entrepreneur that wants to start a new project and at the same time test the market place using minimal capital investment.

• The semiautomatic production cycle is such that new tiles are formed on the top surface of aluminium pallets that are pushed by a hydraulic cylinder through the extruder machine. On exiting machine the tiles are cut to length by a knife unit.

• Upgrade to conveyor line and semi-automatic mixer is possible to increase the capacity and level of automation of the line.

MAXIMUM OUTPUT

10 tiles/minute

MINIMUM BUILDING SIZE

16 m x 20 m x 5 m high

INSTALLED POWER

~ 26 kW (mixer included)

PRODUCTION

4000 tiles per shift

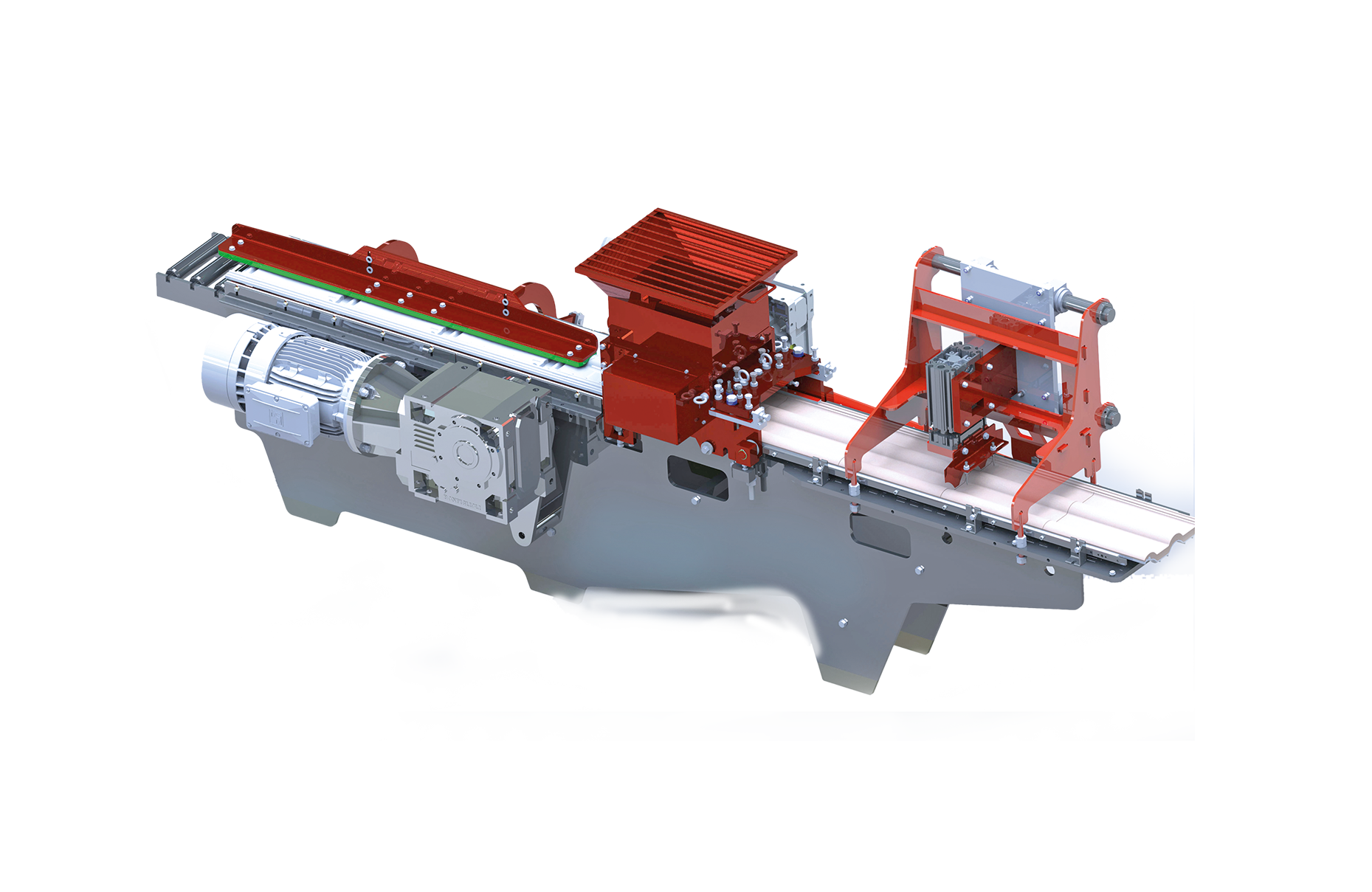

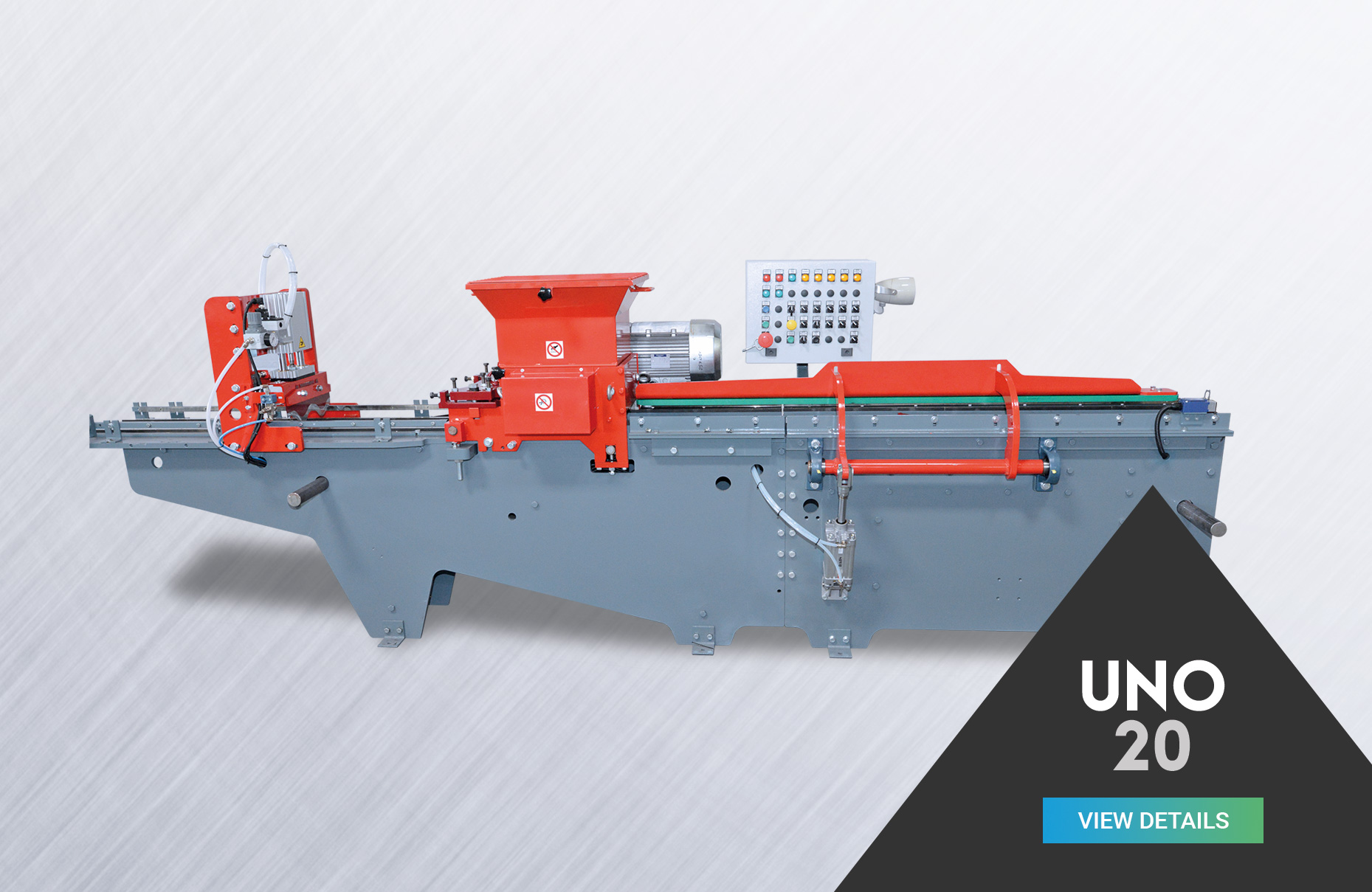

UNO 20

• The UNO 20 has an automatic manufacturing cycle.

• This plant is an ‘inline’ operation that consists of a depalleter, pallet feed conveyor, pallet oiler and the tile extruder machine.

• The ‘heart’ of the system is an UNO 10 machine that now incorporates an alternating higherspeed automated hydraulic underside pallet pushing mechanism.

• PLC control system.

MAXIMUM OUTPUT

18 tiles/minute

MINIMUM BUILDING SIZE

16 m x 30 m x 5 m high

INSTALLED POWER

~ 37 kW (mixer included)

PRODUCTION

7500 tiles per shift

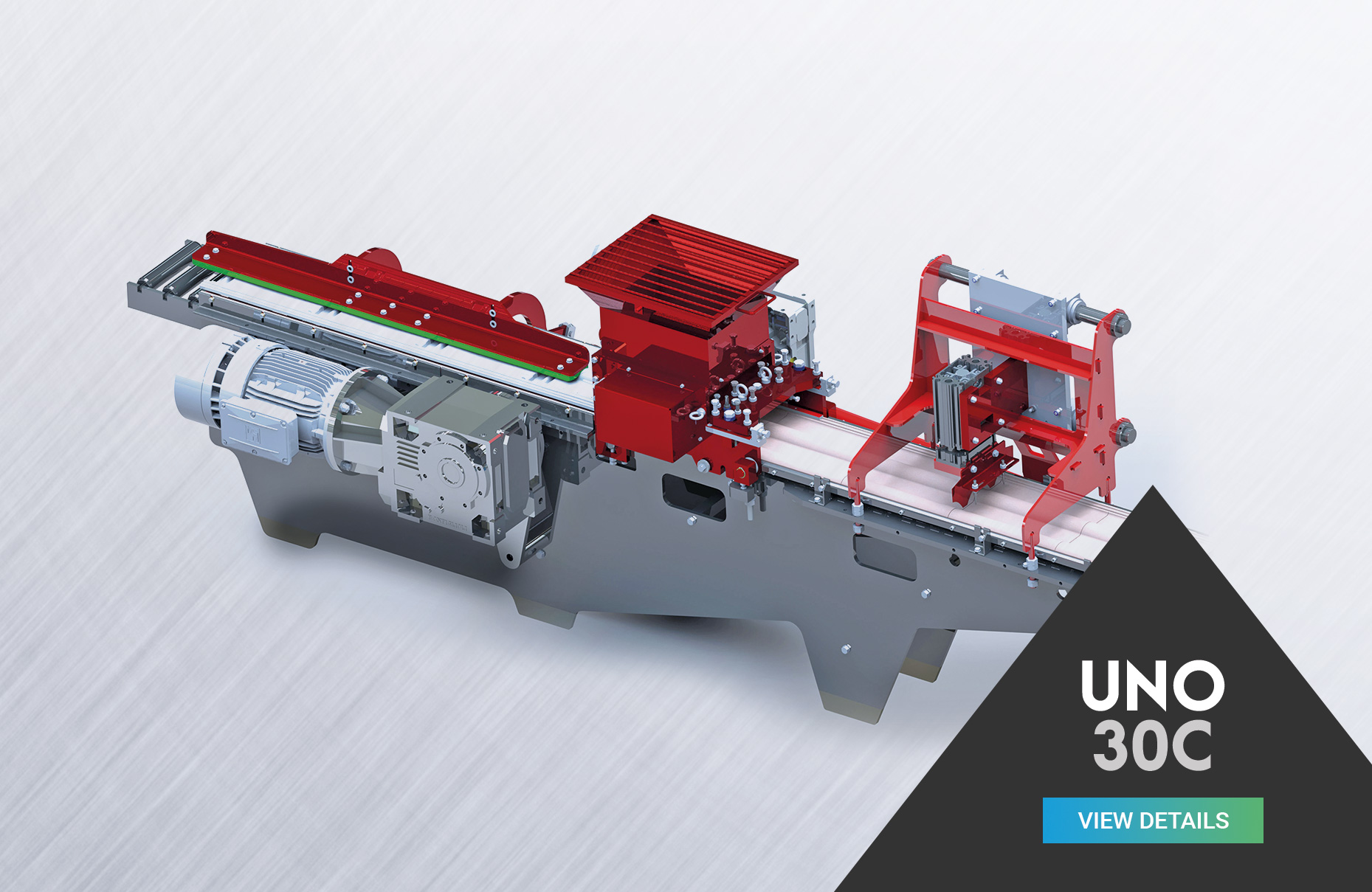

UNO 30C

• The UNO 30C is the NEW highest capacity plant in the VORTEX UNO range of systems. It is a robust system with a continuous propulsion unit.

• The UNO 30C extruder machine operates within an automated manufacturing line that

incorporates a depalleter, pallet feed conveyor, pallet oiler.

• The advantage of this system is that the flow of concrete is a continuous one, with benefits in terms of quality and efficiency.

• The “inline” configuration can be upgraded to a fully automatic one with a complete

conveyor loop.

• PLC control system.

MAXIMUM OUTPUT

30 tiles/minute

MINIMUM BUILDING SIZE

16 m x 40 m x 5 m high

INSTALLED POWER

~ 50 kW (mixer included)

PRODUCTION

12000 tiles per shift