UNO 5 – Set-up plants

2.000 tiles per shift

Ideal for low output, simple but well-organized production of concrete roof tiles. Also, an ideal size ‘set-up’ plant to test the market place. The aluminium pallets, previously separated from the dry tiles, are oiled and manually placed into the tile machine and then pushed through the extrusion box by a hydraulic cylinder. The concrete roof tile, still attached to its pallet is cut to length as it exits the machine. All mechanisms are manually controlled. This is a “multi-profile” machine –different tile types can be produced by it simply by changing the extrusion head and the aluminium pallets to suit the different tile profile. Different facial tile types can also be produced on the machine.

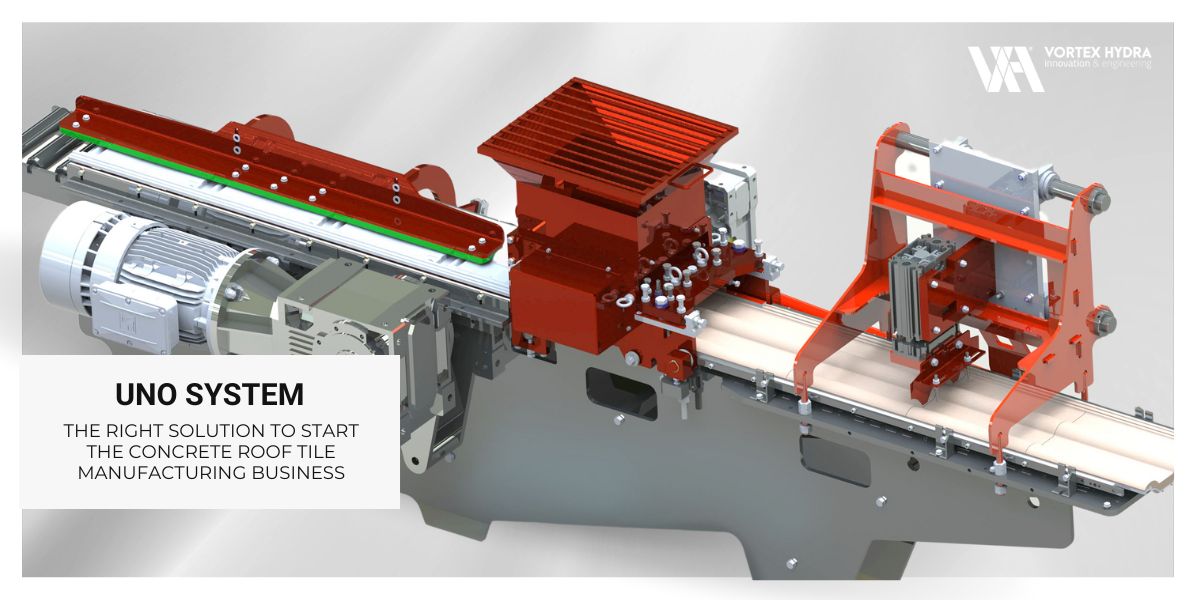

UNO 10 – The heart

4.000 tiles per shift

Ideal solution for entrepreneurs who want to start a new project and at the same time test the market place using minimal capital investment yet still maintaining the option to grow. The extrusion machine has a manual push button to start the production cycle that ends with the new tile being cut by a pneumatic knife. The concrete mixer Is loaded with sand, cement and colour, and automatically feeds concrete to the extrusion machine via a mix feed conveyor. The production cycle is controlled by a PLC unit which allows operation at a speed of 10 tiles per minute.

UNO 20 – Double pulse

8.000 tiles per shift

Ideally-sized plant for a market demand that is in excess of one million of tiles a year. Provided with an automatic concrete batching and mixing plant, it is an ‘inline’ automatic operation that includes a depalleter, pallet feeder, pallet oiler, transport conveyors and tile extrusion machine all this controlled by a dedicated PLC. The “heart” of the system is an UNO 10 machine that now incorporates an alternating higher speed automated hydraulic underside pallet pushing mechanism.

UNO 30C – Continuous flow

12.000 tiles per shift

Ideal solution for customers that require high concrete roof tile production, minimal labour requirements and who wish at the same time to optimize their initial capital expenditure. The tile extrusion machine is a robust system with a continuous propulsion unit and can produce tiles at a rate of 30 tiles per minute. The automated concrete batching and mixing plant is suitably sized to produce concrete at a higher capacity to fit the new extruder speed. The advantage of this system is that the flow of concrete is not subject to any start/stop typical of smaller extruders, with benefits in terms of quality and efficiency. This plant can be easily expanded to an automatic operation by installing a rack loading/unloading and/or a finished tile auto-packaging.